WELDING

Technique, Inc. takes on all aspects of producing parts — including assembly, welding, hardware and coatings.

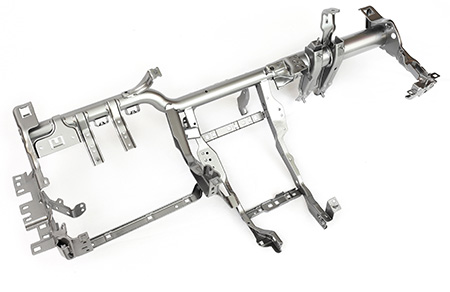

WELDING AND ASSEMBLY

- Full welding capabilities with certified welders on-site

- MIG, TIG, Fusion, Spot, and projection welding

- We can install projection weld studs and weld nuts

- We design, build and certify all weld/assembly fixtures as needed in-house

HARDWARE

- We’re fully capable of installing weld nuts, weld studs, pem nuts, pem studs, and any other type of hardware required.

- We can machine or turn custom pieces of hardware if not readily available.

FINISHES/COATING/HEAT TREATING

We have same-day or next-day sources for all types of finishes/coatings, including:

- E-coat

- Powder coat

- Zinc or nickel plating

- Chrome plating

- Heat treating

- Auto-deposition

- Many others

Technique offers a full range of additional services and we’d love the opportunity to discuss how we can help!

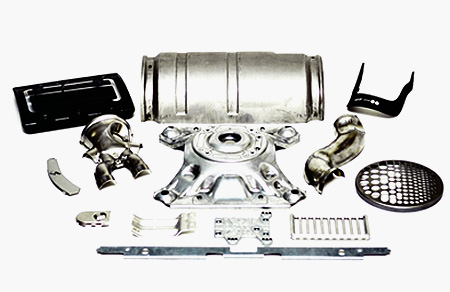

PROGRAM MANAGEMENT

Technique, Inc. can take on full program management responsibility for plans that involve assemblies with high numbers of component parts — even if it includes parts outside of our product areas.

TURN KEY SOLUTION

We can take on the following tasks from start to finish:

- Creating all component parts, including metal stampings, bent and straight tubing, machined and turned parts.

- Outsourcing and management of all parts outside of our product areas.

- Purchasing all necessary hardware.

- Designing, building and verifying any necessary assembly fixtures and gages.

- Welding or assembling the components per specifications to create the finished part.

- Fully inspecting the assembly in our quality lab.

Do you need program management for a current project?

Have Technique call you now and discuss how we can help!