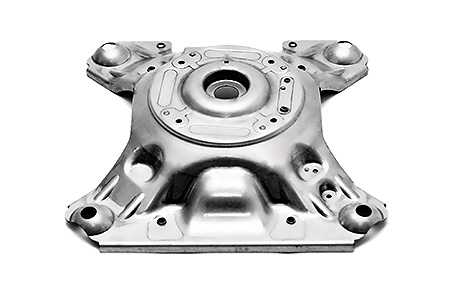

METAL STAMPINGS

Technique, Inc. produces metal stampings the way your company needs them: RAPIDLY, with absolute precision and extreme repeatability. We offer the best lead times in the industry and work aggressively to meet the needs of our customers.

We’re able to work with all types of metals with thicknesses as thin as aluminum foil to metals over 1/2″ thick; including carbon steel, stainless steel, aluminum, high strength low alloy and many others. Our expertise extends to parts ranging from small, intricate parts to large, heavy gage parts.

At Technique, Inc., absolute precision and extreme repeatability are of paramount important to us. We hold tight tolerances for your projects. We ensure your parts are built to your specifications — every part we produce is shipped with a full quality control package, ensuring your parts are built to your precise specifications.

FORMING

- We form parts of all levels of complexity with accuracy and repeatability.

- Our innovative tooling methods work to minimize costs for your prototype or low-volume manufacturing.

- We utilize state-of-the-art, five-axis laser-cutting machines to reduce the cost of development and tooling.

- We offer industry-leading turn-around times on all of our formed parts.

BENDING

- From simple, straight bends to complex brackets, Technique, Inc. can handle any type of project.

- Our large standardized tooling inventory can complete a variety of common bends and shapes efficiently and with lower costs.

- Need specialized bends and gussets? Technique, Inc. can build inexpensive custom tooling to complete your project quickly.

- We work agressively to keep lead times short, and can produce product in days — not weeks.

DEEP DRAW

- From basic drawn parts to extremely aggressive draw ratios, our highly experienced technicians are ready for your project — no matter how complex.

- We utilize next-generation tooling simulation software to optimize tooling line ups prior to cutting tools — resulting in reduced time and cost.

- We offer a variety of standardized tooling inventory for many common pre-form draws.

- Our advanced press technology coupled with our state-of-the-art, five-axis lasers facilitate the prototyping and low-volume manufacturing process.

HYDRO-MECHANICAL FORMING

- We offer minimal tooling for formed parts and aggressive deep drawn parts.

- We utilize a pressurized oil cavity to form parts around a punch, without the need for a die in order to greatly reduce the number of hits needed to form parts.